Case studies

Dorset House, London

At A Glance

- three 10m boreholes in 200mm casing with installations

The Site

Dorset House is a site located off the Marylebone Road (A40) in central London. The borehole positions were inside a car park with a ceiling height of 3m.

Scope

S I Drilling utilised the Low Headroom Rig which can function with a minimum height of 3m. We drilled holes in 200mm with varying depths to a maximum of 10m. Our fume extraction kit was used on several of the holes as they were located underground and therefore limited fresh air.

Equipment used on this job

West Ham United Football Ground

At A Glance

- 25 boreholes

- 10m -30m bgl

- 150mm, 200mm and 250mm casing

The Site

West Ham United Football Ground, East London. Site investigation required to assess the approach for redevelopment of the grounds. The site is built on thick layers of lime stone and other dense materials in the Lambeth group.

Scope

This six-week project used 250mm, 200mm and 150mm casing. The drilling was extremely difficult at times, due to the limestone layers encountered in the Lambeth Group. S I Drilling found the solution to this problem by means of a 250mm sectional tool which helped keep the borehole straight when drilling through cohesive materials. To reduce casing from 250mm to 200mm, the sectional tool allows the casing to reach the base of the hole without touching the sides.

Equipment used on this job

Wreningham, Norfolk

At A Glance

- Water Well

- 200mm and 250mm casing

- 40m bgl

The Site

Wreningham is a site in our home county of Norfolk. Like many Norfolk sites, it is built on layers of chalk. The water well was drilled for domestic purposes for a private home owner.

Scope

The project involved drilling a well in 250mm and 200mm to enable the land owner to pump water from the chalk layers at depth. Water boreholes are extremely unique and often unpredictable from hole to hole on the same land just meters apart. This particular well, after considerable research took approximately one week. The client was extremely appreciative of the successful job and water yield produced.

Equipment used on this job

Appleford Station Oxford

At A Glance

- One 15m borehole at railway station

The Site

Appleford Station, Oxfordshire, required borehole drilling on grass areas either side of the railway tracks. One borehole only accessible via a footbridge across the track.

Scope

Our De-mountable Rig can be transported and assembled in almost any location, which made it a perfect choice for this project. The rig and drilling equipment had to be taken down flights of steps, from a bridge down to the trackside, and then carried on trolleys down the platform. Our four person crew manoeuvred equipment across rough ground approximately 50m behind the platform to the borehole locations. Our heavier items were transported via a stairclimber. The boreholes were drilled in 150mm casing to a depth of 10m.

Equipment used on this job

Willoughby Lane

At A Glance

- 50 boreholes

- 8m -50m bgl

- 150mm, 200mm, 250mm and 300mm casing

- Monitoring and Recovery wells installation

The Site

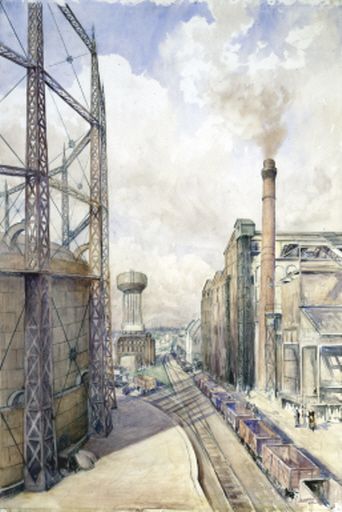

Willoughby Lane is a 100 acre old gas works site, situated near Edmonton. The site is registered as a RED site. Historically large gasometers had leaked gas oil into the ground over many years.

Scope

Due to the hazardous nature of the site, stringent Health and safety measures, over and above typical locations, have been implemented. S I Drilling have been involved on the site since early 2016. Boreholes have been drilled to a maximum depth of 50m using 300mm, 250mm, 200mm and 150mm casing. As instructed, our skilled teams have installed valuable stainless steel standpipes in some of the boreholes. The monitoring and recovery wells will be used in a pumping and filtration process to help clean the soils.

Equipment used on this job

M4 Motorway

At A Glance

- Multiple boreholes

- Maximum depth 50m

- 150mm, 200mm and 250mm casing

The Site

The location extends along the M4 either side of the M25. Boreholes vital to assess the required process to upgrading to ‘smart technology’ being developed and upgraded along the route.

Scope

Numerous boreholes have been, and continue to be drilled to a maximum depth of 50m. SI Drilling have been one company along with others as part of the M4 redevelopment. We used 250mm, 200mm and 150mm casing to achieve the depths required. Drilling progression has needed to coincide with strict Road Traffic Managements and road user needs. S I Drilling have had between 1-2 rigs on this project since May 2016, involving both day and night drilling shifts.

Equipment used on this job

Our Lady of Lourdes School, London

At A Glance

- Six 20m deep cable percussion holes with SPTs and UT100s and standard plastic U100s

- 50mm standpipe installed

- Three Hand dug inspection pits to inspect existing foundation structure

- UXO ordinace

- 150mm and 200mm Stainless Steel Casing

The Site

Our Lady of Lourdes is a Catholic primary school in London. Possible contamination and UXO risks. Drilling was required during school term time.

Scope

Six boreholes drilled were located within the grounds of a primary school and requested to assess geotechnical properties as well as contamination levels of the soil to inform feasibility studies for re-development schemes. We used 200mm and 150mm casing to a maximum depth of 20m. To minimise disruption and damage to the school surroundings, protective ground mats and clean drilling processes was used. We worked alongside UXO specialists who carry out ordnance clearance testing. Safe drilling practise of 2m of 200mm stainless steel low magnetic casing was used with additional standard casing to enable the hole to get through the Made Ground.

Equipment used on this job

West / Central London

At A Glance

- one 20m borehole basement level inside existing building

- SPT testing

- UT100

- D and B samples

- Pipe installation

The Site

Located in the Westend of London, where subterranean building and development is increasingly necessary, the site required in depth investigation into soil strata to determine future construction. Drilling inside an existing building requested.

Scope

This project was undertaken inside an existing building using our De-mountable Rig since the only access was via a stairway. With our de-mountable rig we are able to deconstruct the rig in sections , mobilise through doorways and down stairs to reassemble at borehole position. This rig is capable of being assembled almost anywhere. Once erected, the frame is as powerful and strong - if not stronger- than a standard rig, due to its smaller size. The borehole was drilled using 150mm casing. Testing and sampling taken insitu and 12m pipe installed